The Thermostatic Expansion Valve (or thermal expansion valve), commonly referred to as the TXV (or TEV), is among the most popular throttling devices utilized in air conditioning and refrigeration systems. This valve automatically maintains proper refrigerant flow in the evaporator according to the load inside it.

It increases the refrigerant flow when the load inside the evaporator is lower and does the opposite when it is higher. As a result, the compressor functions properly, and you achieve efficient operation in your refrigeration or air conditioning system. If your Air Conditioner is not functioning properly in the San Marco, CA area, call us to have a Technician dispatched. There are a multitude of reasons why your AC is performing poorly and we’ll diagnose it quickly.

Types of Thermostatic Expansion Valves

Let us begin by looking at the kinds of thermostatic expansion valves available. You can find two primary types of these valves: externally equalized models and internally equalized models.

Externally Equalized Models

These thermostatic expansion valves utilize the evaporator outlet pressure, causing them to compensate for any pressure drop through the evaporator. You can use these valves on any extensive system typically exceeding 1-ton capacity. In addition, you can incorporate them into any system using a distributor.

Internally Equalized Options

These types utilize evaporator inlet pressure to form the closing force on the thermostatic valve. Hence, using an internally equalized model in a system with a sizeable pressure drop through the evaporator causes issues. Such a situation causes the valve to go into a more closed position by increasing the pressure below the diaphragm, leading to a superheat higher than desired.

How a Thermostatic Expansion Valve Functions

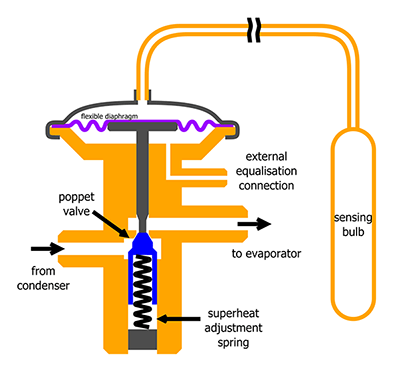

A thermal expansion valve measures the pressure and temperature at an evaporator coil’s end using a bulb and a tube referred to as an external equalizer. The equalizer measures pressure and offers a closing force whereas the bulb measures temperature and delivers an opening force. Moreover, the TXV has an ergonomic spring that can incorporate an adjustable tension, providing extra closing force.

When these forces operate correctly, the valve achieves a balance to maintain the evaporator superheat to the set levels intended at the evaporator’s end. This balance enables the thermostatic expansion valve to serve its purposes effectively. These include keeping the evaporator active, minimizing refrigerant pressure and adjusting refrigerant flow to the requirements.

Thus, the valve can maintain superheat levels within specific operational conditions and ranges. This operation ensures optimal overall performance to keep your premises comfortable.

How Does a Thermostatic Expansion Valve Fail?

Your thermal expansion valve can fail when the device is too far open or too far closed. Too far open, also called overfeeding, occurs when the system feeds the boiling refrigerant too far through the evaporator coil. This condition becomes evident in a low superheat. On the other hand, too far open, also termed underfeeding, means your system is not feeding sufficient boiling refrigerant through the evaporator coil. Consequently, superheat becomes too high at your evaporator outlet.

These failures typically result from moisture or contaminants within your system that reach the valve, causing restrictions or sticking. Besides this, valve malfunction can occur when you have an external equalizer designed with a Schrader core but not a core depressor installation.

Notably, it is advisable to verify the bulb placement, insulation and strapping when your TXV is overfeeding. The valve can stay too far open if the numbing does not correctly sense the suction line. It is best to get professional technicians to examine your system to ensure the correct diagnosis of a TXV problem.

Many people misdiagnose their thermal expansion valve when they experience low evaporator load or airflow. This mistake occurs because, upon finding low suction pressure, they assume that a system has low refrigerant. As a result, they begin adding refrigerant to address the issue, and the TXV responds by closing even further. When they realize that the suction is not increasing, people often conclude that the issue is thermostatic expansion valve failure.

Therefore, it is vital to find expert air conditioning technicians who can consider all readings available, including suction and liquid line temperature, for proper evaluation and diagnosis of any TXV problem. This enables you to avoid costly errors and unnecessary repairs.

Signs of a Problematic Thermostatic Expansion Valve

When the device’s liquid line has restrictions, it causes the compressor, evaporator and condenser not to receive refrigerant. These restrictions generally occur when moisture or debris accumulates in the liquid line. You know you have a starvation problem when you notice the following symptoms in your thermostatic expansion valve:

- Low compressor amp draw

- Low evaporator suction pressure

- Low condenser split

- High evaporator and compressor superheat

- Normal to slightly high condenser subcooling

- Somewhat high discharge temperature

- Short cycles on the low-pressure control

- Low condensing head pressure

Benefits of a Thermostatic Expansion Valve

Understanding the functions of a thermostatic expansion valve lets you know the advantages you derive from the device. These include the following.

Facilitates Optimal Performance

A thermostatic expansion valve permits the evaporator to be active during the cooling procedure. It constantly adjusts the refrigerant flow for the modified superheat, ensuring that the evaporator functions optimally.

Adjusts Refrigerant Flow

The TXV modifies the refrigerant flow into the evaporator to match the contained heat load. This adjustment facilitates an instant response to a decrease or increase in the heat dispelled by your electrical device. It will address any temperature fluctuations within the enclosure for efficient flow and performance.

Yields Greater Power Efficiency

The compressor can also operate at its optimal capacity according to the refrigeration load on your system. A lesser load means it must compress refrigerant and function on lesser capacity, using less electricity. Conversely, the compressor can perform at higher capacities when the load is higher.

Improves Temperature Control

A thermal expansion valve aids in controlling the temperature in the enclosure as it controls the refrigerant flow. Other devices that regulate flow have less flexibility. A capillary tube, for example, enables continual refrigerant flow, making an instant response to a changing heat load difficult. A TXV is an active device, and it can maintain the enclosure temperature closer to the predetermined point temperature than a passive device could. Additionally, it has a lower time constant required to achieve your desired temperature in case of an abrupt increase in heat load.

Lessens Risk of Compressor Failure

The TXV ensures that the liquid refrigerant completely vaporizes in the evaporator to eliminate liquid slugging. This function also removes the risk of liquid refrigerant particles getting to your compressor and compromising its normal function.

Tolerates Refrigerant Charge Variation

A thermostatic expansion valve can conveniently handle refrigerant charge variation because it adapts the refrigerant flow to suit the heat load. In contrast, a passive expansion device such as a capillary tube is less tolerant. Such models require a specific refrigerant amount in the cooling loop, a vital parameter that can influence an enclosure air conditioner’s performance.

At Oak Island Heating and Air Conditioning, we offer unmatched experience and service to help keep your home comfortable throughout the year. We have a set of core policies that ensure everyone we serve with an outstanding customer experience, and they apply to every assignment we undertake. From us, you can expect exceptional expertise, timeliness, free in-home consultations for new installations, no hidden costs and respect for your property.

We provide residents of San Marcos, CA and the San Diego County area with first-rate cooling and Indoor Air Quality services including repair, installation and maintenance. Call us today for more information.